An eyebolt combines a threaded shaft (or shank) with a complete, round loop at one end. The typical application of an eyebolt is to be threaded to the top of a structure so that a rope or cable can be fed through the ring. This may be used to lift or secure the object. In other cases, it may also be used to secure another object, using the eyebolt as a connecting point on the anchoring structure.

Typically, eyebolts are made from either steel or stainless steel (either 304 or 316). The former type is usually forged whereas the latter is usually investment cast. Therefore, steel eyebolts are typically somewhat stronger despite the greater material strength of stainless steel eye bolts.

All SPEP eyebolts are rated with specific fload capacities. Breaking load (also called ultimate loads) refers to the amount of force or weight the part can withstand before failure. No part should ever be used at or near its breaking load. Working load is the maximum load that should be applied to a part under normal working conditions. The ratio between the breaking load and working load is called the safety factor, which can vary depending on the application. However, some providers also offer unrated eyebolts. These are only intended for very light usage and should not be used to lift or secure any significant loads.

How Are Eye Bolts Measured?

There are a few ways that eyebolts can be measured. The two most significant measurements are the load capacity rating and the thread size. In SPEP’s catalog, the rated capacity range from 460 pounds to 38,000 pounds per bolt for our most heavy-duty eye bolts. These capacities are only for vertical loads. Any angular loads may substantially reduce the maximum capacity of the eyebolt.

Thread size is represented in two numbers. The first is a measurement of the diameter from the outer thread on one side to the outer thread on the other side. The second part of the measurement is the number of threads per inch, which are generally categorized as either fine threads (UNF) or coarse threads (UNC). Coarse threads will have less threads per inch than fine threads. All standard SPEP eyebolts feature coarse threads.

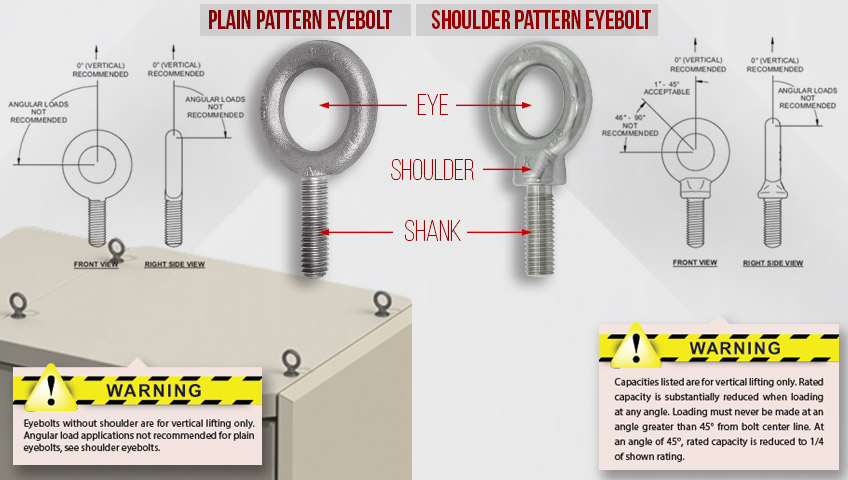

Eyebolts may also be measured by their other dimensions. These include the outside diameter of the eye loop, the inside diameter, and the length of the threaded shank. For shoulder eye bolts, the distance from the center of the loop to the bottom of the shoulder and the length of the shoulder flange may also be provided. All other dimensions can be inferred from these measurements.

Types of Eyebolts

In addition to the above measurements, eyebolts are typically described by their material (usually steel or stainless steel) and form factor. SPEP has two types of eyebolts in our catalog: plain pattern eyebolts and shoulder pattern eyebolts. Stainless steel eye bolts are available in both 304 and 316 stainless steel.

Plain Pattern Eyebolts

A plain pattern eyebolt has the threaded shaft directly connected to the round eye. This design is very simple and typically has a lower profile than a shoulder eye bolt. However, it should never be used for angular loads in any situation (all loads should be directly in line with the threaded shaft).

Shoulder Pattern Eyebolts

A shoulder eye bolt has a solid reinforced section between the eye loop and the threaded shaft. This helps to strengthen the bolt and redirect angular forces, minimizing the likelihood of shearing. Therefore, they can be used for loads that are not exactly in line with the shaft. However, it should be noted that the breaking load decreases dramatically as the load angle increases, and loads should never be perpendicular to the shaft. 45 degrees is the maximum acceptable load angle, at which the rated capacity is reduced to 25% of its normal value

In theory, shoulder pattern eyebolts offer no advantages over plain pattern eyebolts for vertical loads. However, if there is any risk of lateral forces affecting the load, a shoulder pattern bolt should be used.

What Is an Eye Bolt Used For?

Eyebolts are primarily used for lifting and securing materials. They can be connected to materials, containers, and other items to provide a point through which a rope or cable can be secured. Eyebolts are designed primarily to handle loads that are being lifted directly from above. However, our steel and stainless shoulder eye bolts can also be used for angular loads within 45 degrees of the centerline.

Load angles can be managed using a spreader bar. This allows the load to be dispersed evenly and at the correct angle for each of the eyebolts.

To achieve their maximum load capacity, eyebolts must be screwed in fully. Otherwise, they may easily break even with a lighter load. This is especially significant when using shoulder eyebolts for angular loads. Always be sure to check that eyebolts are fully engaged to the surface they are installed on as part of safe lifting practices.

Proper use is essential for safety and productivity. A misused eyebolt may break, potentially causing expensive damages and even serious injury.

Common Eyebolt Uses

There are applications for eyebolts in industrial, transportation, residential, and many other settings. The following are some of the most common:

- Adding one or more connection points to a material or a container for lifting purposes.

- Creating connection points for industrial and construction rigging.

- Adding tie-down points on trailers, boats, trucks, and other vehicles.

- Connecting decorations or other light needs in residential or business settings.

- Many more uses that involve connecting a rope or cable to a material.

Whatever your eyebolt needs are, contact SPEP today to find exactly what you are looking for. If our catalog doesn’t have it, we can engineer it! Custom engineering and 3D prototyping are what set Sierra Pacific apart from the rest. Contact us today.

Editor’s Picks

Sierra Pacific Engineering College Scholarship Program

Feb 7, 2022

What is Supply Chain Management, and Why Is It Important?

Jan 13, 2022

How To Make Threads in Solidworks: Become a Solidworks Expert

Nov 10, 2020