ENGINEERING

WORLD-CLASS BUSINESS-TO-BUSINESS SUPPLIER WITH OVER 35 YEARS EXPERIENCE IN THE ACCESS HARDWARE MARKET.

CONTACT USSierra Pacific Engineering Your Custom Hardware Manufacturer

In some industrial hardware applications, you simply cannot settle for whatever is available off-the-shelf. You need a part that can match your exact specifications. Sierra Pacific Engineering and Products offers custom hardware engineering services to help you get the right product at the right cost and delivered at the right time. When you work with a SPEP hardware design engineer, your needs will always come first.

Why Sierra Pacific

SPEP is ISO 9001:2015 certified, and we have been operating under ISO quality management guidelines since 2001. Our commitment to quality has helped us satisfy customers by helping them navigate the entire product lifecycle from concept to mass production for countless custom hardware designs. We have also earned over 80 patents through our hardware engineering services.

Our products are backed by a wide range of quality assurance tools and procedures at our disposal to cover a wide range of situations and requirements. These include capabilities for Production Part Approval Process (PPAP) levels 1-5, Statistical Process Control, Corrective Action Resolution (multiple formats), digital/optical calibration inspection tools, in-house pull and drop load testing, salt spray testing, and custom durability and cycle testing. We can also provide FAIR/1st Articles, ISIR, DFMEA, PFMEA, PFC, etc., and can incorporate testing at outside certified labs for more sophisticated requirements.

-

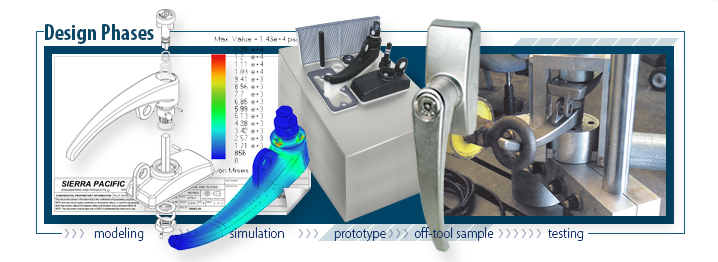

- Right Product

To ensure that we create the right product, we start with an in-depth computer-aided design process in Solidworks. By 3D modeling the part, creating detailed drawings, and running FEA simulations with PDM Pro Data file management, we are able to ensure that the final part will perfectly match your requirements.

We also encourage collaboration between your engineering team and our own to solve problems and ensure that the final part will be the right product for you. Our goal is to help you establish your brand as an industry leader through a partnership with SPEP.

- Right Product

-

-

- Right Cost

Of course, meeting your functional requirements is not enough. We also need to ensure that the part is available at the right price. We will refine and optimize the design by adjusting material, aesthetics, and functional design to offer you the greatest cost savings possible. Our ability to balance cost and performance has made us the go-to custom hardware engineering team. - Right Time

By applying our time-saving techniques such as rapid prototyping and FEA simulation, we can get to a finalized design faster. We then move swiftly into production tooling and validation. After off-tool samples are approved, we will stock the parts in our closest warehouse to your dock. Lead time becomes transit time from our facility to yours, allowing you to practice Just In Time (JIT) inventory and receive parts at the right time.

- Right Cost

-

All About 3D Models and Prototyping

3D modeling with Solidworks is a key part of our design and prototyping process. Our goal is to have a collaborative design process with our customers. To aid this, we offer free, downloadable 3D models that engineers can use in their designs. We also offer part prototyping as part of our iterative design process, so you can run real-world testing or work with our custom hardware engineering team to test parts.

Guide You To Expert Design

At Sierra Pacific Engineering and Products, we are experts in designing latches, hinges, and other industrial hardware components. We can produce parts using any industry-standard manufacturing process. Use our design guide to get started planning your custom part. We are always here to help. Contact our sales team today!