CUSTOM PRODUCT DEVELOPMENT GUIDE

WE OFFER CUSTOM HARDWARE DESIGN and ENGINEERING SERVICES TO GET THE RIGHT CUSTOM PART FOR YOUR NEEDS

WHAT WE OFFER

Whether we are making custom latches, unique handles or any other specialty part our top priority is to deliver

The right part

At the right time

For the right price

This manufacturing design guide outlines what to expect while partnering with SPEP to develop a new item.

We have optimized our engineering design process to have the perfect balance of being responsive to your needs and maintaining the highest level of detail. We use state-of-the-art technologies including Solidworks 3D CAD Modeling and Rapid Prototyping to ensure you receive your custom product as quickly as possible.

If needed, our team will work collaboratively with you throughout the process by managing the project based on your outlined requirements and iterative feedback to create a brand new design. We can also review designs for parts you already use and propose problem-solving engineering improvements, or even simply quote a pre-existing design that you provide.

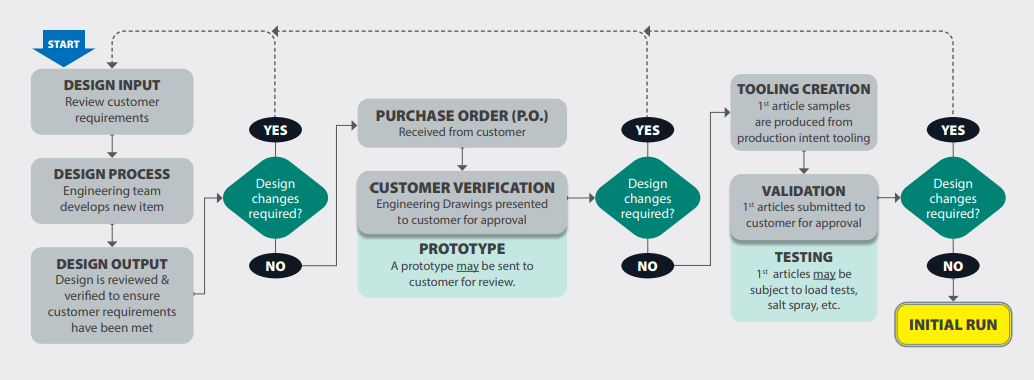

SIERRA PACIFIC COLLABORATIVE DESIGN PROCESS

We begin by qualifying the potential project to confirm it makes mutual business sense in terms of volumes, timeframe, and other expectations. Once the scope of work is understood, we will outline any potential costs for design services if required. For most high volume projects, development costs are waived with the commitment of a production order upon completion of acceptable design work. We are happy to work with you to find the right solutions that will work for your budget.

When we are designing a custom product, our ultimate goal is to deliver the right part for your application. We begin with your requirements, which can be delivered as CAD files, sketches, written requirements, or modifications on an existing part. Using your input, our engineering team will design the new product and deliver engineering drawings, renderings and/or prototypes for your evaluation and approval. Through each of the design process steps, we take a collaborative approach to ensure your satisfaction:

Iterative Design Process

Our custom hardware engineering process is built on the ideals of collaboration and communication with our customers. As the design progresses, we periodically solicit your feedback to ensure that the part conforms to your exact requirements. Of course, we understand that different customers have different expectations for their required involvement in the process. As such, we can work as independently or as collaboratively as you prefer.

3D Modeling & Rapid Prototyping

We use 3D modeling to create highly accurate designs for each part we manufacture. Using these models, we can produce 3D printed rapid prototypes to aid our collaboration with your team. 3D models are also helpful for quality assurance throughout the design process since they can specify characteristics which are difficult to dimension on a 2D drawing. Additionally, we can provide our model files in any file format required so that you can drop the part right into the final assembly using your own CAD tools to validate.

Analysis & Testing

We also use finite element analysis (FEA) to ensure that parts will satisfy the necessary specifications for strength and durability. We can design products to meet your specific requirements, standard industry specifications of your choice, or common best practice recommendations from our engineering and application experts. Once physical samples of the parts are produced, we can conduct testing for load rating, corrosion resistance, cycle reliability, or any other performance attributes critical for your application. Results from any testing conducted are provided for reference and comparison to your own evaluation of the off-tool samples. We ensure that your new product will meet your needs and ISO 9001:2015 certified quality management guidelines.

Contact Sierra Pacific Engineering

Interested in SPEP designing a custom product for you?

Contact us today to learn more about our products, design services and other solutions